I was given an exceptionally warm welcome by Mitch and the rest of the crew. Everything seemed to be in order for an informative day at Stone. The next thing I remember is the Gargoyle swooping in from the rafters and whisking me off to a gigantic pest containment cage so that I could be held under his watch until further notice. It seems my parking lot entry steamed him up and gave him reason to distrust me. No bother, I was given coffee and snacks during my stay in the cage and I found it quite pleasant. From my position in the cage I was able to notice how tightly spaced the newly added fermenters are. I was also able to see the warehouse operations crew in action as they performed their finely orchestrated forklift ballet in order to keep product moving out of the facility.

Upon convincing the gargoyle I was not a threat to Stone or it's brewers I was released into the hands of Tim Roser. Tim's food science degree led him to seek a career in brewing. His 4th day of solo brewing led him to be saddled with this traveling brewer asking a quarter of a million questions about a process Tim is just starting to fully grasp. Some guys have all the luck right? Tim and I did get a chance to discuss the learning benefits of explaining what you are doing during each minute of your day. Tim is one brewer in a team of brewers working in 24 hour, 7day a week schedule. In this format the team of brewers have taken Stone from 400Bbls of beer in 1996 to somewhere near 150,000Bbls this year. Stone IPA will be nearly half of that production. Tim was temporarily freed from his purgatory by Jeremy Moynier who led me off to detail more of the fun at Stone.

Jeremy obtained his love of beer in part through harvesting grapes at a winery. He said "Finishing the harvest and being covered in sticky grape juice really made us thirsty. We drank a lot of beer at these times and this is where I developed my taste for, and love of craft beer." When it was time for a career change Jeremy found Stone and applied for a brewing job here. There was a filtration job available at the time and it quickly led to a brewing position when Jeremy showed his talent for the job. Jeremy and I checked out Stone's wood aging area and discussed a collaboration in the works with some other breweries involving used Scotch barrels. I got an opportunity to ask questions about why everything looks so new. It turns out that Stone has been in this facility for only five years, has filled it to near capacity with vessels, and is nearly ready for another facility to brew from. There are many other interesting projects coming your way from Stone in the months and years to come. Check the Stone website for good information on those. After discussing as many things as my caffeine addled mind could muster I finally shut up and let Jeremy talk. It turns out that the greater San Diego area is going through a food and beer renaissance. This is turning an ever increasing amount of focus on local beer and food. This new awareness of local beers has created an environment in which more than thirty craft breweries are able to thrive. In addition to thriving the breweries created the formidable San Diego brewers guild and invited all the area beer bars to join as well. This makes for a very open and friendly local brewing scene in which ingredients are sometimes shared. In addition to adding benefits for all of the brewers and bars involved it makes for a great yearly beer fest in Liberty Station. I even got to hear about why there is no sign on the brewery in one sentence - "If people want to find us they will." The amount of customers in the visitors center and pub at 11:30AM on a Monday morning instantly added weight to that statement.

The Gargoyle was watching.....

After a nice walking tour of the brewery with Jeremy I was invited to join him for lunch in the beer garden. Lunch was sausage and sour kraut with some other accompaniments. It was great to get a nice lunch without having to pay. After this I was determined not to raise a fuss over the brief, possibly necessary, caging.

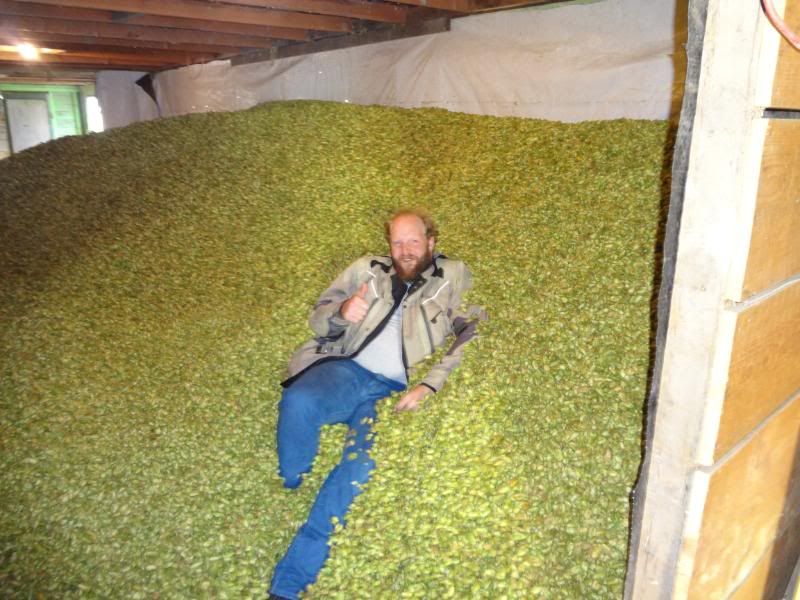

After being fed I re-joined Tim for some more brewing. I was asked if I would like to add hops to a batch of Stone IPA. Of course I do! I actually got to make an addition to a batch of beer that many people will enjoy and that is a very cool thing, no matter how many times you've done it. After the hop addition we headed off to the lab to find a number of interesting things. I will repeat what I said earlier in this project, the lab is usually the place to be for fun.

That guy to your right is Phil. He is wearing black latex gloves in

an effort to keep his bare hands off of the vanilla beans he is breaking up. He is breaking those vanilla beans into small pieces so that they may be added to a 1000mL flask to be heat sterilized in an effort to make them suitable to add to a wooden barrel full of porter. All of this labor is done so that people can enjoy the barrel aged vanilla porter Stone releases locally from time to time. I think you know what to do when you see Phil.

After talking with Phil for awhile about his day and his job, missing another valuable chance to learn to do a yeast cell count in the process, I moved out to the cellar to find Tim again. The freedom to roam for a minute allowed me to spy an astounding array of colors out of the corner of my eye. I followed it to the best of my ability. It was moving so fast I wasn't sure what it was until I caught the bright streak back in the lab.

That is Drake. This is Drake's second week at Stone. He is the newest member of the brewing staff, and the resident wardrobe expert. His story at Stone begins with a move across the country. He has been working in breweries for 4 years but your guide on this journey has forgotten to write down where. He wanted to continue the non stop adventure that brewery work has to offer, and he is getting a change in scenery to boot. In the first week of his employment here he helped chop upwards of 2500 pounds of pumpkin for a project that is in the works. This is common ground for new brewers. When you start at a brewery you will rarely get a chance to actually make beer. Instead, your efforts will normally go towards the process of creating the things that make beer happen, whether it is cleaning tanks or chopping gourds your early days in a new brewery will be spent as a facilitator.

I did finally catch up with Tim again. This time he was cleaning up a mess that I helped make while we were measuring and adding hops. I decided it was time to give him a break and I left to go grab a beer before I departed.

This is Kayle. There is a good chance that you will see him when you visit Stone. If you're nice he might pour you one of the great Stone offerings. He also might pour you any one of the 32 great beers available in the classy on premise bistro. He will probably be incredibly patient with you when you forget the in house internet password 15 times in a row. Before you leave the pub don't forget that Kayle should be tipped heavily for these services.

This is where I ended my day at Stone. I was welcomed to sit with Phil, Kihei, and Matt to enjoy some after work (for them) beers. It was nice to taste, discuss, and enjoy some great beers with these guys and not be in a position where I felt the need to constantly ask questions. While what I am doing is not exactly work, it is not exactly relaxing either. Luckily it is a hell of a lot of fun.

Cheers to everyone reading. Thanks very much to Stone.

Look out for that gargoyle.